Screw for Wood to Metal and Roofing Series

BDN Fasteners offers TIMBER-Tite™ and TRUSS-Tite™ self-tapping metal roofing screws. Self-tapping metal to wood screws, TIMBER-Tite screws, are designed for fixing metal roofing sheets or wall claddings to timber, whereas TRUSS-Tite™ is designed to fix steel roofs and floor trusses.

Basically, all self-drilling and self-tapping screws are capable of tapping threads, where the main difference is that self-tapping screws normally come with either a blunt head, sharp point, or a reduced drill point. BDN Fasteners offer self-tapping screws for wood to metal, allowing for quick fastening of metal roof or wall panels to wood.

Self-Tapping Metal Roofing Screws Series – TRUSS-Tite™

Blunt-headed metal roofing screws, such as the TRUSS-Tite™, is designed for truss components assembly, fixing into steel. These types of steel normally come with pre-punched or pre-drilled holes, and the blunt, slightly tapered leading threads make it easier to fix the sheets down.

Self-Tapping Metal to Wood Screws Series – TIMBER-Tite™

Our sharp-pointed metal to wood screws, TIMBER-Tite™, are designed for fixing roof sheeting to timber. The longer versions, such as the T17CG1265C3N or T17CG1250C3N, are designed for crest fixing, while shorter versions, like the T17H1020C3N, are designed for valley fixing. People often ask why screws should be fixed down on the crest but not the valley. The main reason is that water runs by gravity and flows to the lowest point. If fixed on the valleys on rooftops, it might increase the risk of water pooling around the screws and, over time, cause rust.

Shorter self-tapping metal to wood screws, which come with what we call a “reduced” drilling point, provide the same function as a sharp drilling point but drill faster through thin metal sheeting. They are also much more effective at clearing off excess swarf. It is difficult, if not impossible to add flutes on smaller sharp pointed screws due to manufacturing limitations.

Features of BDN Screws for Wood to Metal

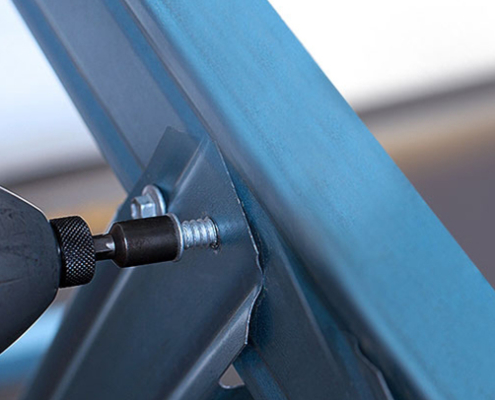

For roofing sheet fixing screws, always check if they come with a knurled, fluted, or slotted shank, and if the upper threads are larger in diameter compared to the lower threads. You might notice that the majority of BDN self-drilling and self-tapping roofing screws are equipped with both. The larger diameter upper threads provide good pullout strength for the whole setup under high winds, and the slotted Scratshank design clears out excess swarf, which might damage EPDM washers if leftover, which could result in leaks.

Are you looking for something?

View more products or directly contact us!

If you need more information about our products or get samples, we are very happy to help!

Learn more about roofing screws >>

Impact of metal roof screws rusting & how to prevent the damage

BDN Fasteners

BDN Fasteners (Broaden Worldwide Co., Ltd) is an ISO-9001 Certified Quality Supplier-Manufacturer of Australian Standard AS3566 self-drilling and self-tapping screws in various coatings for steel to steel and steel to timber applications. Our headquarters are in Taiwan and we operate sales and marketing offices in India and Thailand.