FIXING CLADDING TO METAL

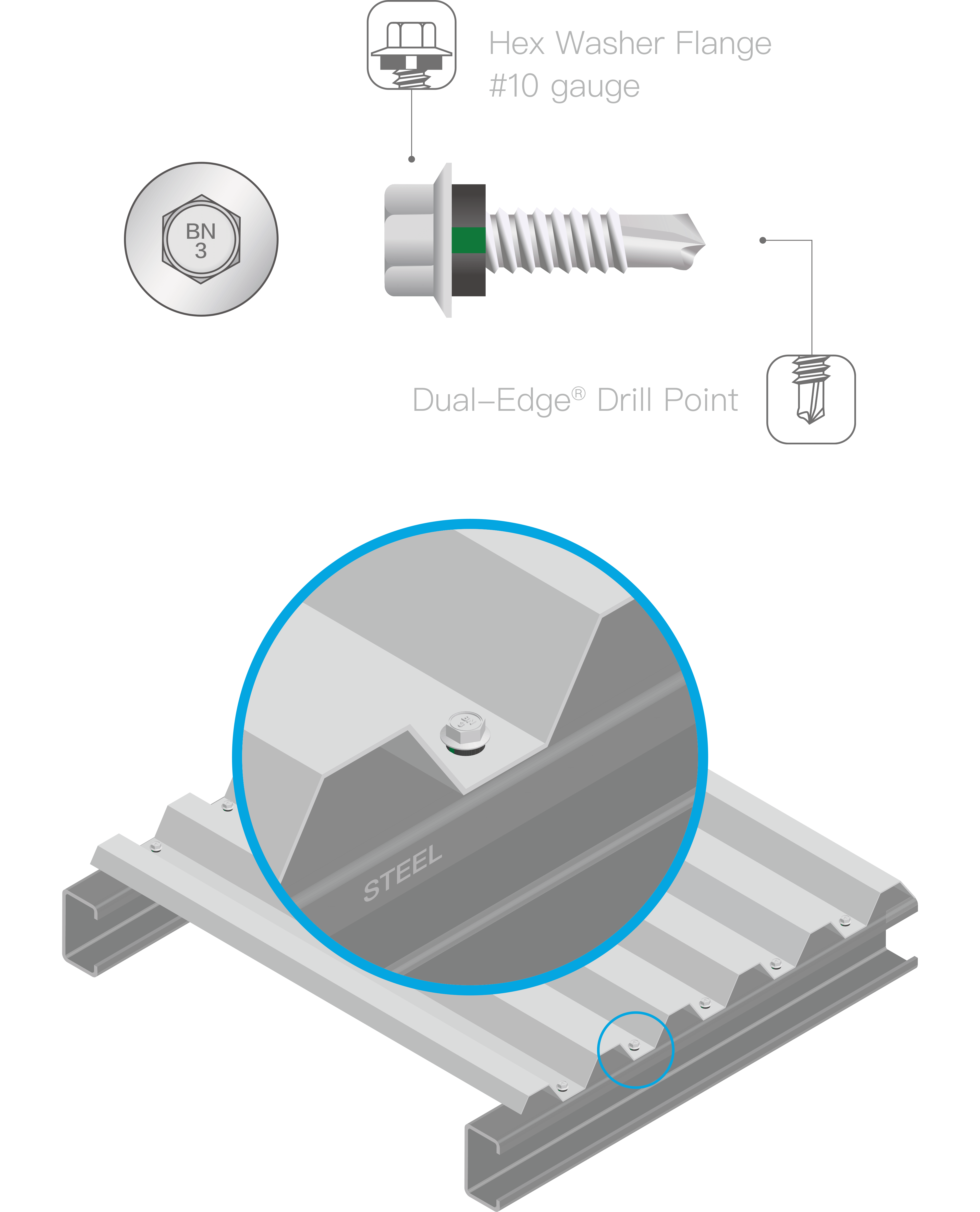

METAL-Tite™ – VALLEY FIXING FASTENERS #10 Gauge

Carbon steel fasteners for fixing steel sheets onto steel substrates

STEEL PENETRATION

Max 4.0mm thick (For #10 gauge)

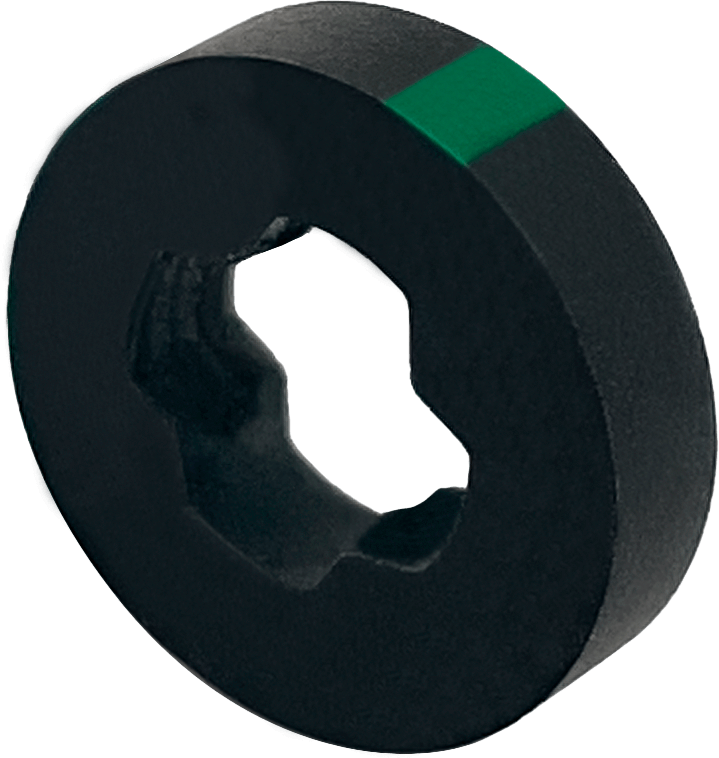

ADAPTER TO USE

Magnetic Hex Socket (5/16″)

PRODUCT FEATURES

Hex Washer Flange

Dual-Edge® Drill Point

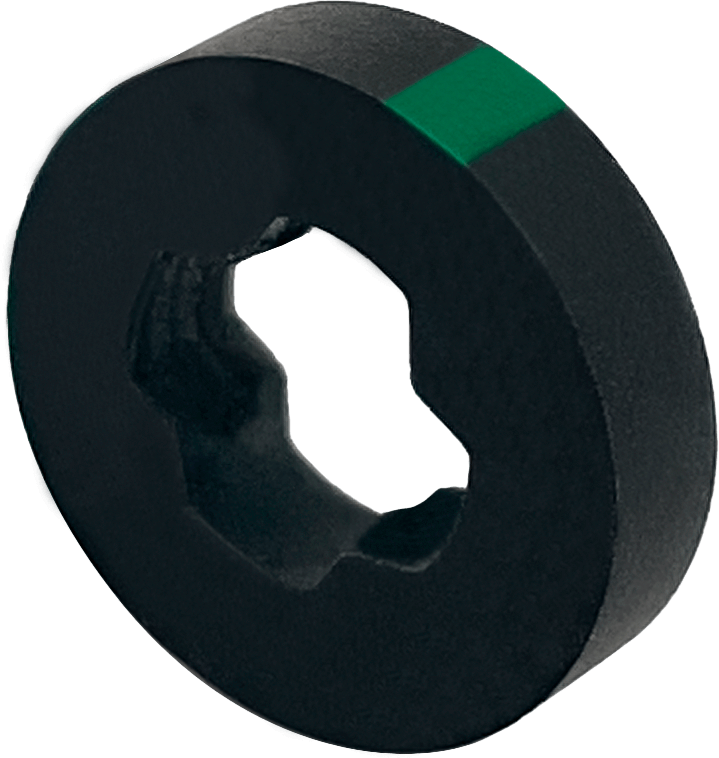

WASHER

Eco-BDN® Green Washer

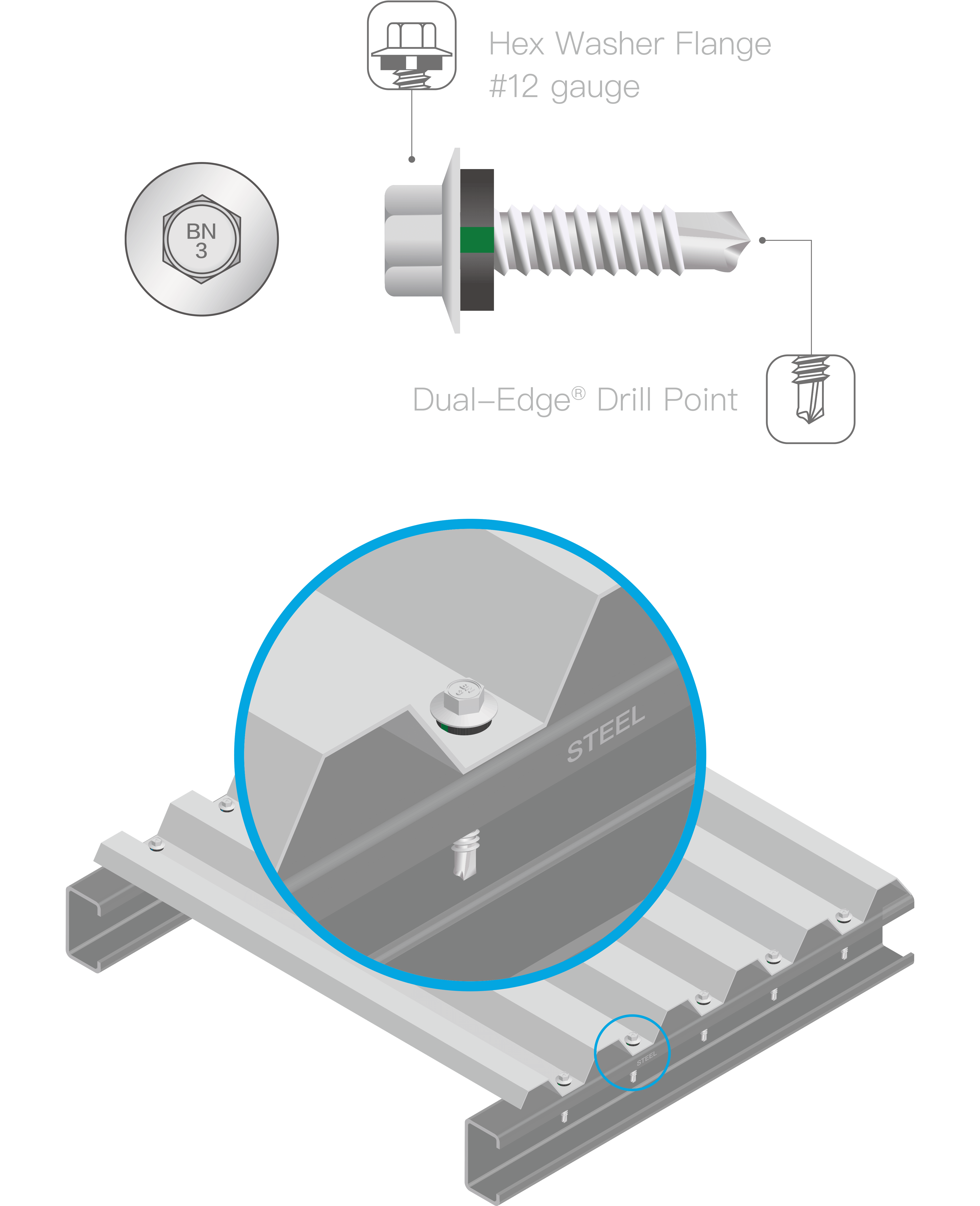

FIXING CLADDING TO METAL

METAL-Tite™ – VALLEY FIXING FASTENERS #12 Gauge

Carbon steel fasteners for fixing steel sheets onto steel substrates

STEEL PENETRATION

Max 6.0mm thick (For #12 gauge)

ADAPTER TO USE

Magnetic Hex Socket (5/16″)

PRODUCT FEATURES

Hex Washer Flange

Dual-Edge® Drill Point

WASHER

Eco-BDN® Green Washer

PART NUMBER

For size not indicated below , please contact for further information

Full Thread |

|

#12 Gauge

|

#10 Gauge

|

|

SDHC1225C3N 12-14 x 25mm |

SDHC1016C3N 10-16 x 16mm |

|

SDHC1230C3N 12-14 x 30mm |

SDHC1019C3N 10-16 x 19mm |

|

SDHC1235C3N 12-14 x 35mm |

SDHC1025C3N 10-16 x 25mm |

BN3 Head Mark

|

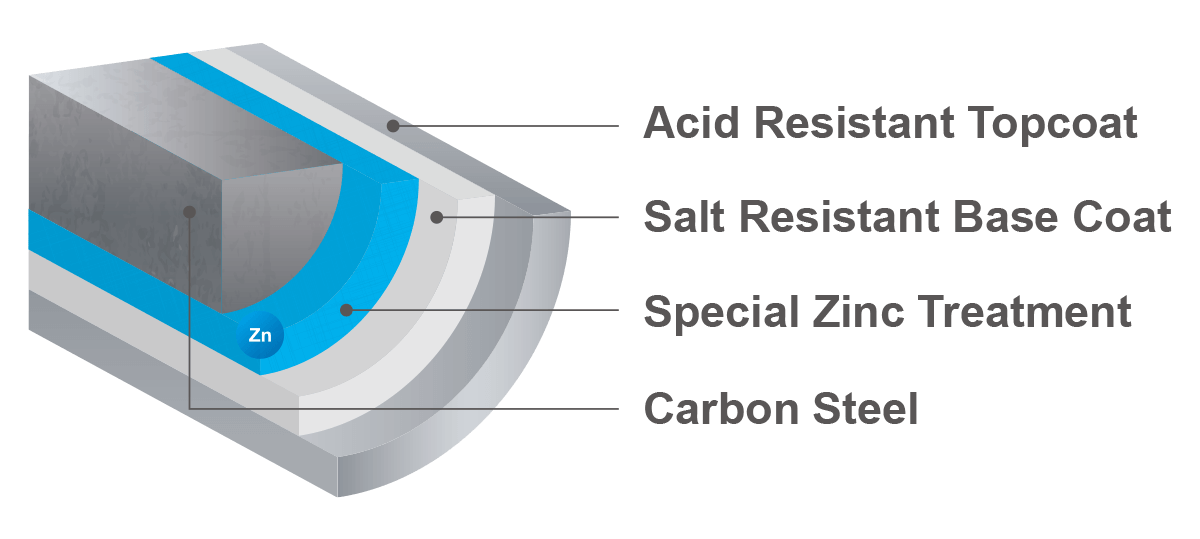

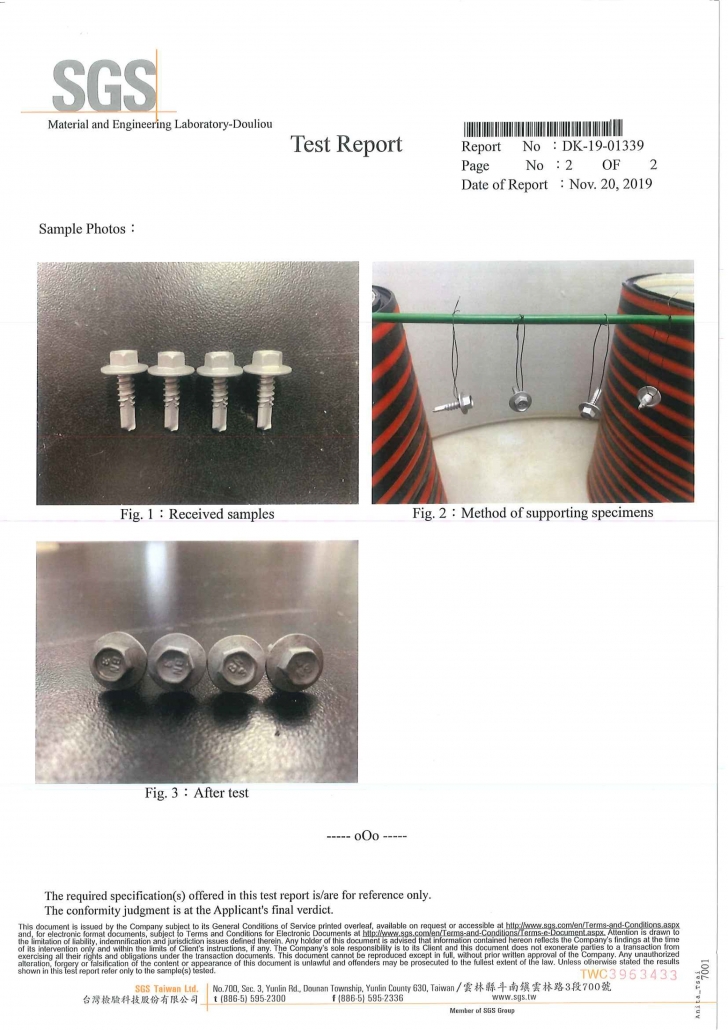

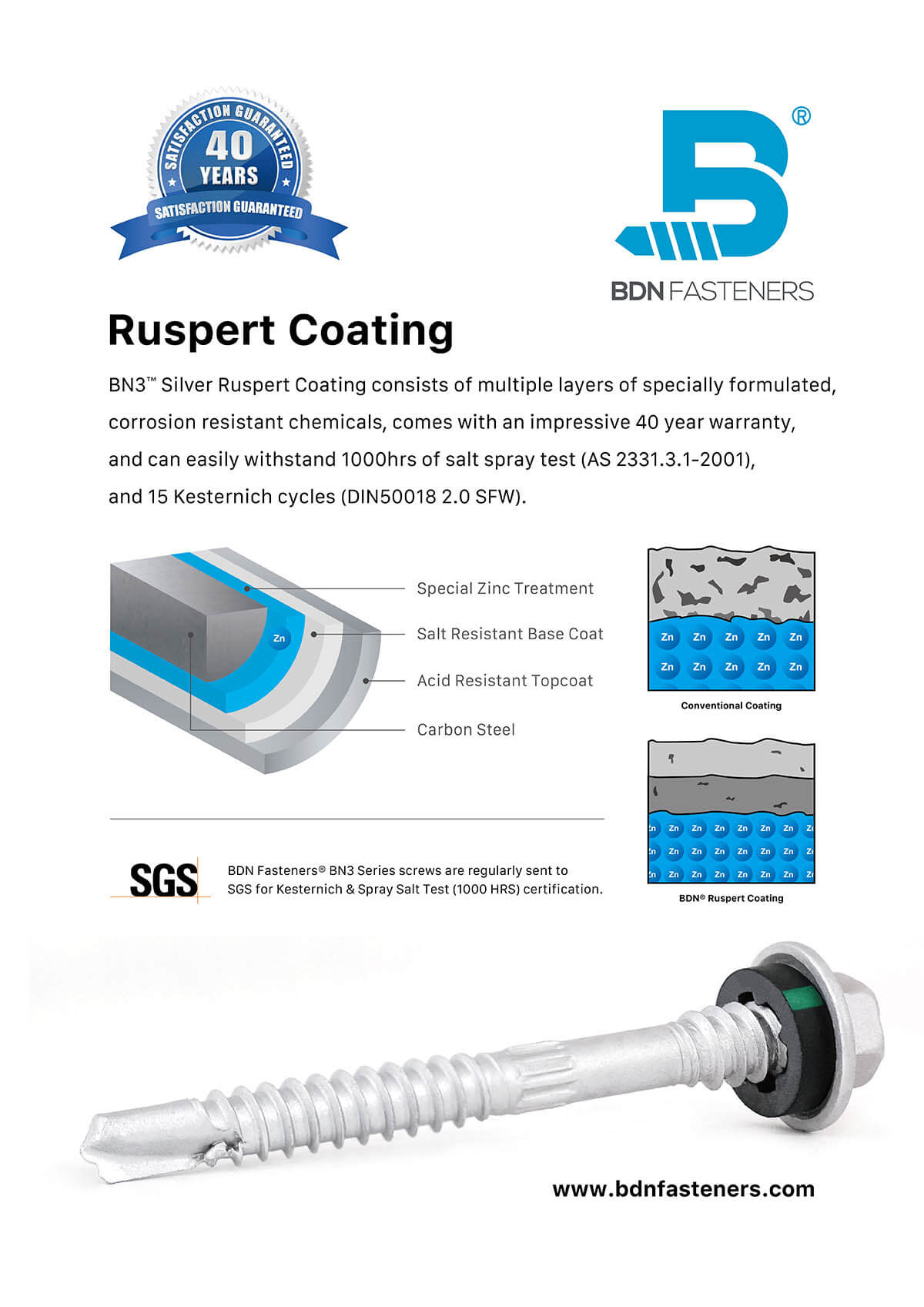

Surface Coating

|

|

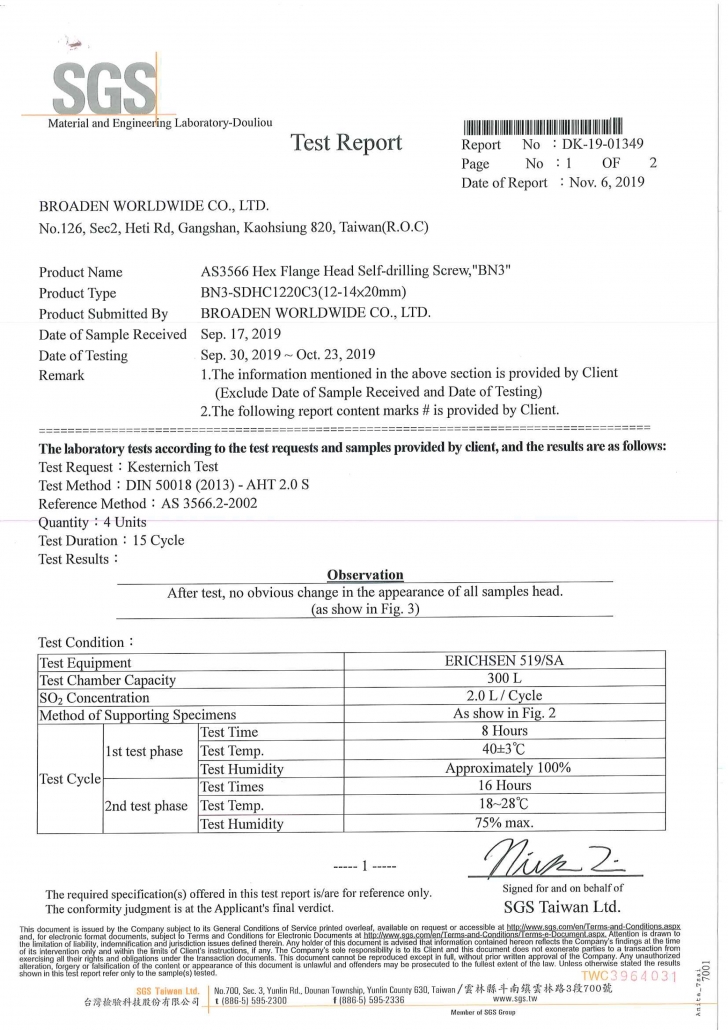

| Corrosion Resistance | Class 3 | |

| Coating Type | Zinc+ Organic Coating (Ruspert) | |

|

SST 1000 hrs + Kesternich 7 cycles |

||

If you need more information about our products or get samples, we are very happy to help!

Fill in the form below and we’ll get back to you as soon as possible.

If you need more information about our products or get samples, we are very happy to help!